Due to the dry summer, a significant number of corn plots were harvested dry and dry . When the corn plant is green, there are enough lactic acid bacteria on the plant for lactic acid formation to sufficiently lower the pH and allow the ensiling process to succeed. In a large number of parched corn plots, this aridity made it quite a challenge to get the silage goodly preserved. In this article, learn more about the effects of heating in the silage and tips for dealing with a heating-prone corn silage.

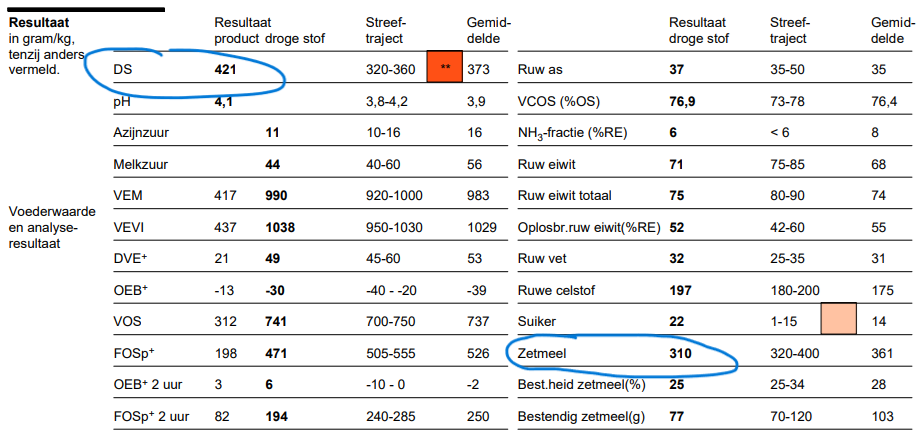

Below is a picture of a silage corn silage from the Eastern Netherlands, which was harvested too early on September 1 due to desiccation and withering. Note the dry matter value and starch values.

What is scalding?

Incubation occurs the moment yeasts can do their job. Yeasts work in an aerobic environment. This means that oxygen is needed to activate the yeasts. The yeasts initiate a process of combustion, converting both sugar and starch into CO2 and water, this process releases heat. The temperature can rise above 50 degrees Celsius in the process! Theoretically, we speak of a heating corn silage at a difference between the corn silage and the outside temperature of more than 10 degrees Celsius, however, at warm temperatures around ensiling this is not always realistic.

Microbial processes in the silage are inevitable; indeed, they are necessary for the silage to be optimally preserved. As in the cow's rumen, it is also important in the silage to manage the microbes as well as possible. When preserving the corn silage, we desire maximum production of acids (for example, lactic acid formed by lactic acid bacteria), this causes the pH to drop, making the corn silage stable and inactivating organisms such as endobacteria, clostridia fungi and yeasts. During these processes, the silage becomes anaerobic.

Lower uptake due to scalding

The fact that something less tasty causes you to eat less or perhaps nothing at all is not foreign to us. This also applies to our dairy cows. Increased intake of forage and other feeds in the basic ration is lurking. In fact; a scalding corn silage can cause other products in the feed mixer, as well as at the feed fence, to also scalp, become less palatable and lose quality. Intake loss reduces milk production (1 kg less dry matter intake quickly gives a loss of 2 kg of milk!). The ration, which has probably been carefully calculated, becomes unbalanced, so you no longer feed what you think you should feed, putting pressure on the health of the dairy cattle (cows that eat less of the basic ration and supplement the ration with a pellet that they are willing to eat can suffer from rumen acidosis, for example).

Feed value reduction

That forage maize changes due to heating is not only physiologically visible, but also the nutritional composition changes. We see a decrease in energy-linked nutrients. The amount of starch, starch resistance and VEM become lower. Combustion takes place and that requires energy. Also, the pH of the corn may rise due to breakdown of lactic acid formed by lactic acid bacteria. In corn silage, the protein present is generally resistant, due to heating, putrefactive bacteria get more chance, which increases the ammonia content of the silage and decreases the DVE in the silage.

Economic impact of scalding

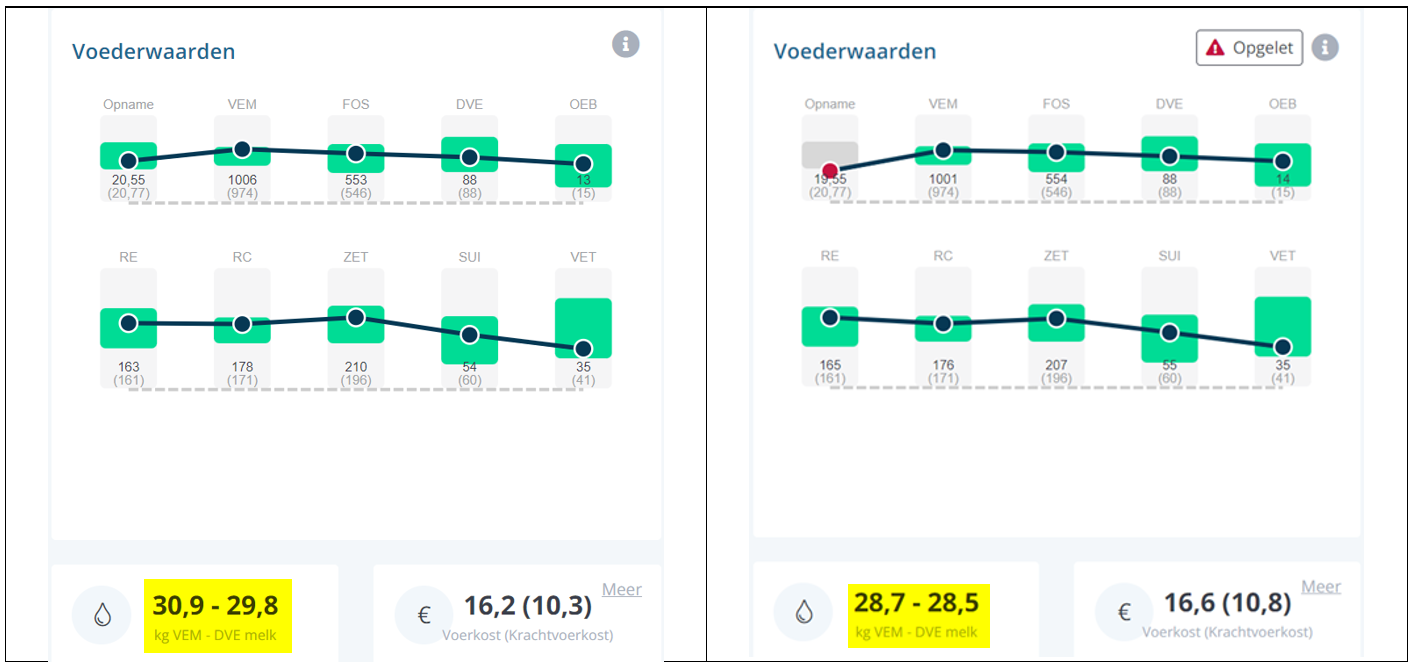

If we optimize a basic ration with 4.5 kg of dry matter from silage corn, 8.5 kg of dry matter from the grass silage, supplemented with resistant soy (0.5 kg) and corn meal (1 kg), and supplement the ration with 7 kg of production pellets, we get a situation where a cow can produce 30.9 kg of milk from energy and 29.8 kg of milk from DVE.

However, if the intake of roughage is one kilogram lower, then without correcting the ration you get a situation where you can see that due to heating the production on the energy side decreases by more than 2 kg of milk and on the protein side by more than 1 kg of milk. You will also see the feed costs per kilogram of milk rise (see figure below, in the left situation you see the ration without heating in the corn silage, in the right situation the ration with heating in the corn silage).

The above does not take into account storage losses arising from the heating of the corn silage, nor the decline in the quality of the other feeds. You often see that when the silage is scalding, a portion disappears into the manure pile, obviously this is an immediate loss!

We can thus conclude that scalding on many farms without correction quickly gives a loss of more than 2 kg per cow per day.

"The business implications are easy to calculate: for example, if you feed a scalding corn silage for a year and have 100 dairy cows in milk, at a milk price of 60 cents, this will cost you: €21,900!"

Farmdesk Staff Member

Dealing with a corn silage that is susceptible to heating

If you have a corn silage that is susceptible to heating due to dry harvesting and a high dry matter percentage, there are a number of measures you can take.

- First, if you do not have a ground cover on the corn silage, you can still choose to use a ground deck to the silage. You will thereby prevent oxygen from easily entering the corn silage, activating yeasts and oxygen-loving microbes. If you do not have a ground cover on your silage, you can apply extra weight to the silage by using a heavy rubber mat or possibly heavy wet silage packs. With the extra weight, you will prevent air from migrating into the silage.

- Measure the temperature of your corn silage, do this in several places, including in the sides of the cut corn silage. When you see an increase in temperature, you can quickly switch. For example, you can then choose to temporarily feed more silage corn to increase the feed rate. You can also temporarily choose to carefully cut out the silage corn with a silage cutter, this will keep the cutting edge neat and less air ingress occurs. It can also help reduce scalding by spraying the cut surface with propionic acid.

- Should you have scalding in the corn silage and feed with a feed mixer, you may choose to use a preservative to be added to the basic ration. An example of such a preservative is Potassium Sorbate, however, there are other preservatives on the market. With a heating inhibitor, you will prevent heating of other feeds. Be careful when adding water, water has a pH of 7 (but tap water can have a higher pH as high as 8.5!). In the base ration, this raises the average pH, which can activate yeasts.

- It may also be advisable to several times a day to feed it is important to thoroughly remove the feed residue.

- For the coming crop year, when choosing corn varieties, you may want to choose varieties that have low susceptibility to bubble burn and other diseases caused by fungi. Also, a variety that stays green longer often causes fewer problems.