Introduction

Over the past few years, Farmdesk has built in-depth expertise around climate science in agriculture. In early 2024, we launched Farmdesk Climate in the dairy industry. Now we are extending this solution to the potato processing sector, which benefits equally from visualizing the climate impact of potato growers.

Farmdesk Climate enables efficient monitoring of the carbon footprint of individual farms. Much of the required data is automatically read in, providing continuous insight and active farmer engagement with minimal effort. A great example of this is the successful rollout of Farmdesk Climate in the dairy sector for Royal A-ware in Belgium, where in less than two months hundreds of dairy farmers were started up with the necessary digital support, without time-consuming individual farm visits.

Besides climate impact, water quality, water consumption, soil condition and biodiversity also play an important role in the potato sector. In this study the focus is on climate impact, the other aspects will follow later.

Methods

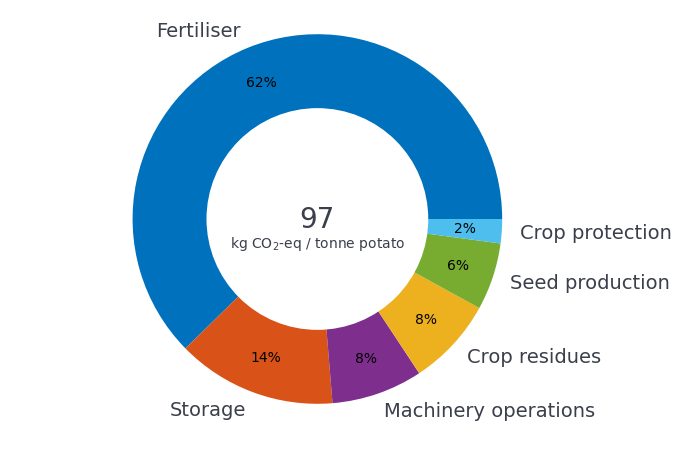

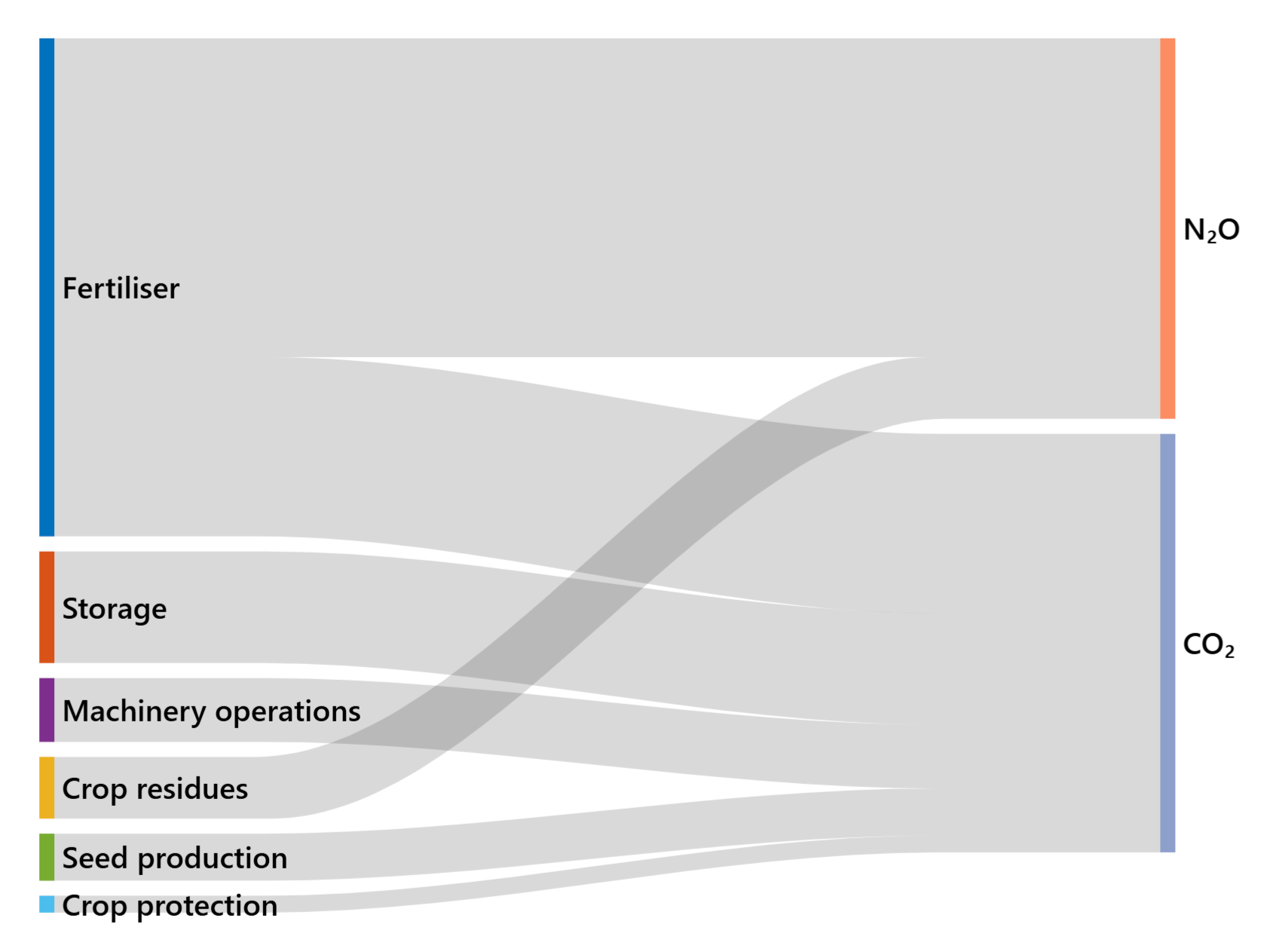

In this publication, we present the first carbon footprint calculation of potato cultivation on an arable farm in Texel, the Netherlands, in the year 2024, calculated with Farmdesk Climate. The cropping plan of this farm included 71 hectares of consumption potatoes, supplemented by seed potatoes, barley, wheat, maize, grass, alfalfa, carrots and sugar beets in the rotation.

A weed treatment was first applied to all potato plots, followed by fertilization with cattle slurry or compost mix. From April to early May, 3 tons of seed potatoes per hectare were then planted, with an initial fertilizer application, a fungicide, and a nematode and rhythm needle treatment also applied immediately. After emergence another fertilizer was applied as well as several treatments with crop protection agents.

During the period from late September to early October, a total yield of 3390 tons of potatoes was harvested, intended for the production of potato chips. This represents an average yield of 48 tons per hectare. Half of the yield was washed directly after harvest and transported to the chip factory. The other half was treated with sprout inhibitor after harvest and stored in a conditioned shed. As of March 2025, these potatoes were also washed and transported to the processor.

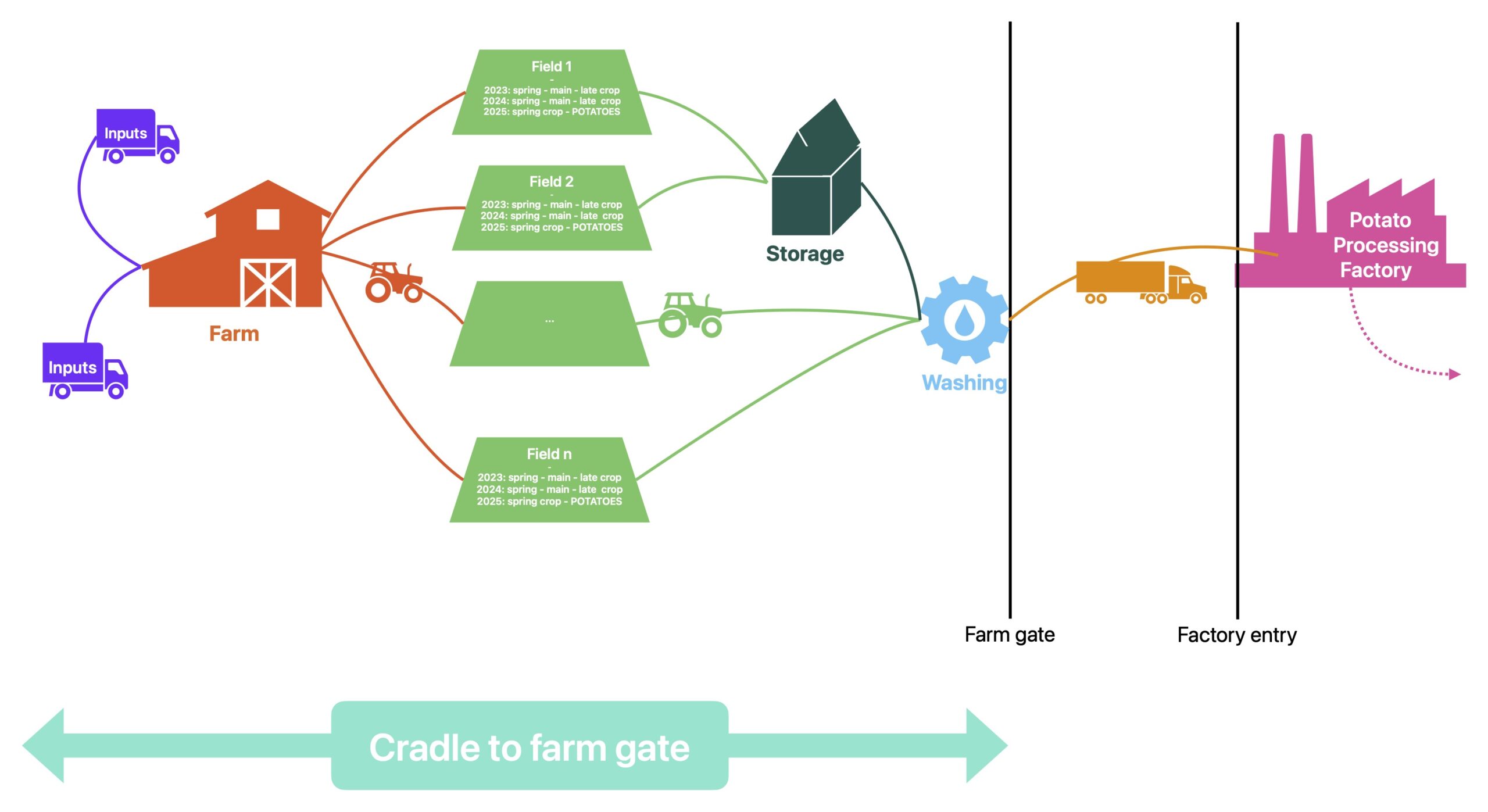

Farmdesk Climate provides the carbon footprint cradle to farm gate, meaning that the carbon footprint is calculated from the origin of all inputs (such as fertilizer production) until the product leaves the farm. In other words, all greenhouse gas emissions directly or indirectly related to agricultural activities on the farm are included in the calculation.

Results & discussion

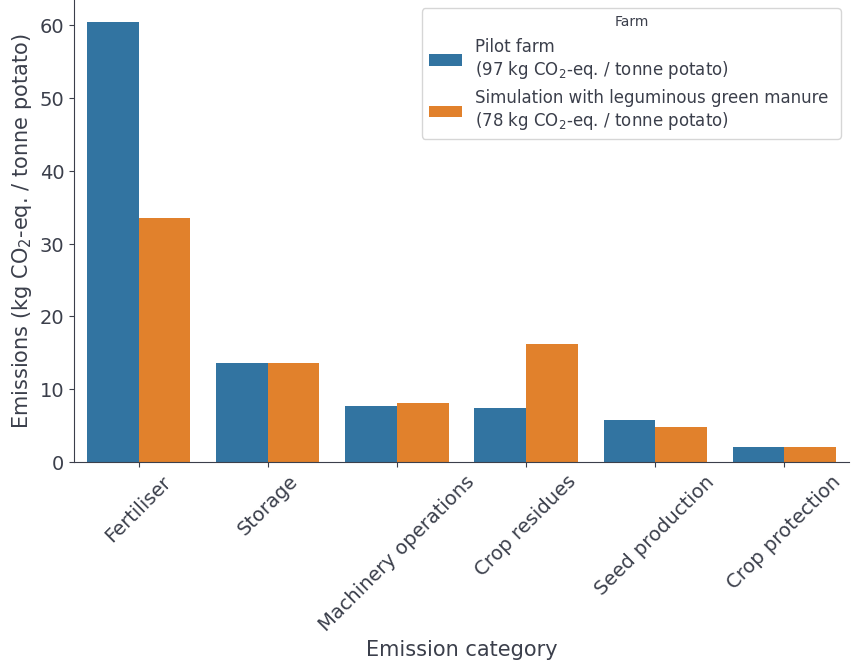

As a final step in this study, we simulated the effect of using nitrogen-fixing green manures as a pre-crop on potatoes, reducing the need for fertilizer. This assumed that nitrogen fertilizer application was reduced by 82 kg N/ha, while potato yield remained the same. The net result is a decrease from 97 kg CO₂-eq/ton to 78 kg CO₂-eq/ton, a total reduction of 19%.

As shown in the figure below, the largest reduction occurs in fertilization: from 61 kg CO₂-eq/ton to 34 kg CO₂-eq/ton, almost a halving. Emissions from machinery operations and crop residues increase slightly, but have a smaller impact.

Results & discussion

"Several potato processors in The Netherlands and Belgium have ambitious targets on greenhouse gas emissions, water use and biodiversity. To achieve these goals, we firmly believe that it is essential to actively engage arable farmers without burdening them with complex administrative tools. Farmdesk Climate offers a user-friendly and effective solution for this."

Jef Aernouts - CEO Farmdesk

References

[1] coolfarm.org

[2] Ponsioen, T., & Blonk, H. (2011). Case studies for more insight into the methodology and composition of carbon footprints of table potatoes and chips. www.blonkmilieuadvies.nl

[3] https://www.klimrekproject.be/akkerbouw/LCA_pilootboeren